5-Axis Additive Hybrid CNC Machining

Innovative, Ultra-precise, Powerful, Compact, Fully Integrated

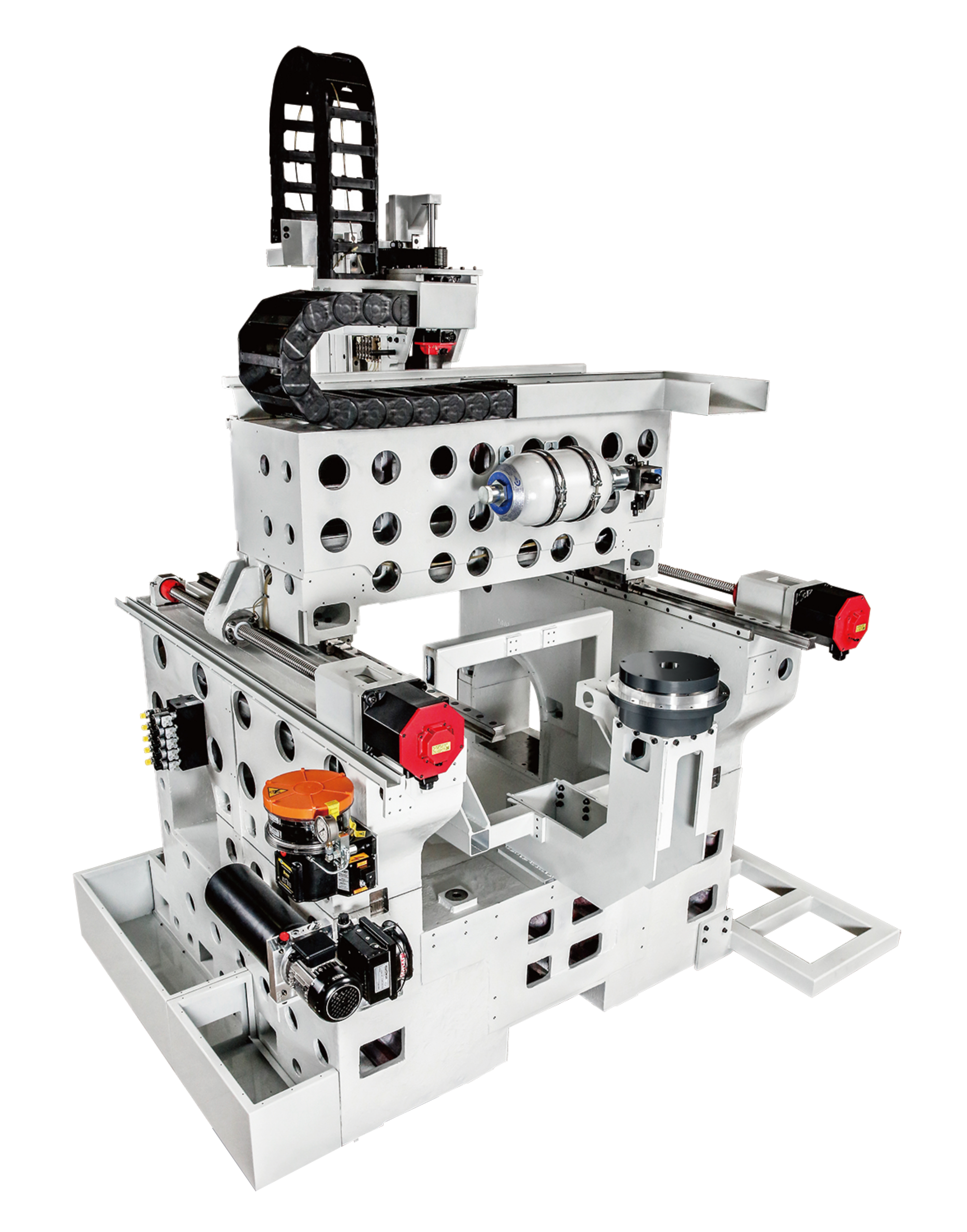

The JUPITER VMX650 FX WLMD Vertical Machining Center is a high-performance, premium machine tool designed to meet the demands of various industries, including aerospace, defense, medical, and automotive. This advanced 5-axis milling machine integrates fully with a Wire Laser 3D Metal Printing head, allowing parts to be printed and machined in the same setup, significantly reducing production time and increasing accuracy.

With its compact footprint, the VMX650 FX WLMD offers a powerful platform that supports maximum capacity and performance. Its design is automation-friendly, with front and side accessibility, and it includes options for pallet pools, making it an ideal choice for high-efficiency manufacturing environments.

Crafted with top-quality components, from the castings to the spindle bearings, Jupiter ensures years of flawless operation. The machining center’s exceptional machining volume, relative to its floor space, guarantees optimal performance and space efficiency. Stay tuned for an updated image showcasing the latest features of this versatile and high-performance machine.

Experience the future of manufacturing with the JUPITER VMX650 FX WLMD, where precision, performance, and cutting-edge technology converge.

Customer-driven Configuration Flexibility

Jupiter partners with the world’s leading CNC system providers to deliver whatever platform you prefer.

High Performance Spindles

All Jupiter spindles feature Japanese bearings and come in dual-contact / Big Plus taper as part of their standard configuration. Each spindle is hand-built by master craftsmen before being precision balanced and run-in for over 72 hours. Direct drive and belt-driven styles are available depending on your application needs.

Premium Ballscrews & Linear Guides

All Jupiter machines come with C1-class premium super accurate ballscrews and roller linear guides manufactured by motion industry leaders for the most demanding applications.

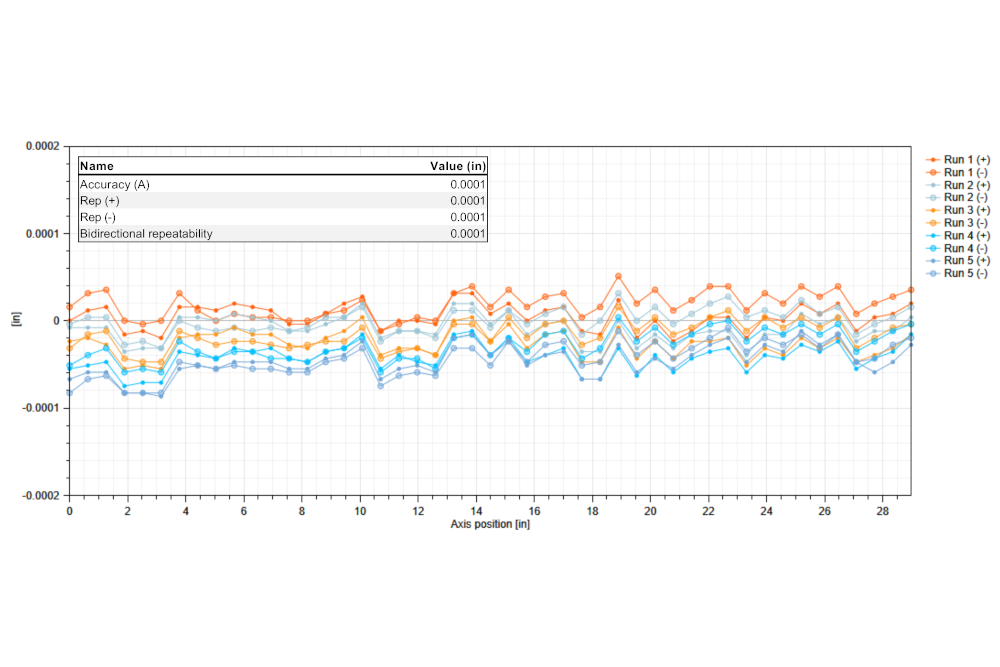

Incredible Accuracy

All Jupiter machine tools are laser pitch error compensated and ball bar inspected both before leaving the factory and at time of installation on the customer’s floor. You deserve micron precision.

Faultless Reliability

Jupiter components are always chosen with long-term reliability in mind, so that you don’t need to keep reliability in your mind. New Jupiter machines come standard with a two year manufacturer’s warranty… but you won’t need it!

Specifications, Standard Features, & Options

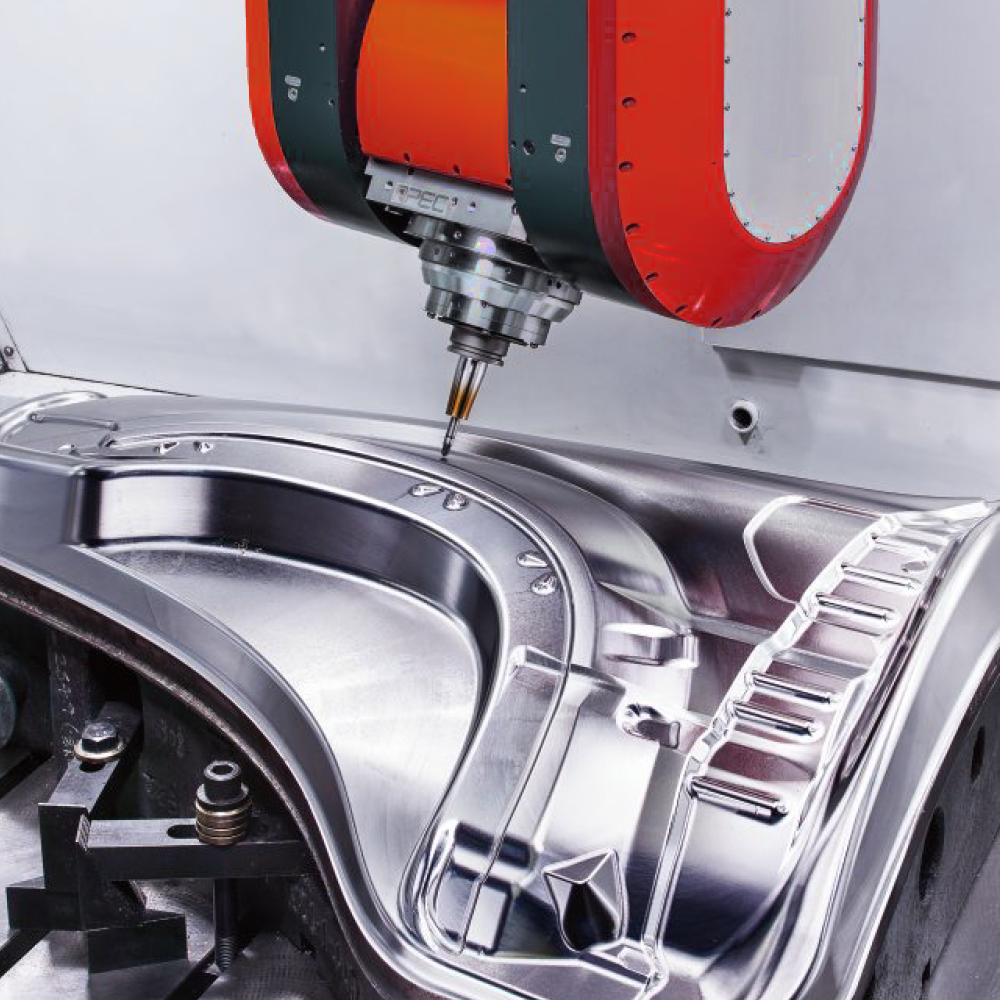

Machine large, flawless molds with the Maglev series.

Jupiter’s Hurricane platform provides simultaneous 5-axis mold-making quality machining performance at a fraction of the price demanded by European competitors. Each machine is tailor-made to your exact requirements and subject to extremely rigorous performance testing before it ever leaves the factory. Hold the impeller test part in your hands before your new Hurricane arrives!

For larger workpieces upgrade to our high speed Maglev gantry platform. Push mold-making performance to the very limit with silky smooth 30,000 rpm HSK spindles, blisteringly fast maglev linear motor drives, and Heidenhain glass scales and encoders!

The Hurricane 650‘s U-shaped casting and spindle cross-rail design provides unparalleled rigidity for a trunnion machine.

Machine specifications published for reference only and are subject to change without notice. Not all features available on all models. Always see your local Jupiter representative for up-to-date information.